The sewing table is completed and deployed to the dining room where it will live as a sideboard when not in use for sewing. I ended up doing water based polyurethane for the finish on top of natural danish oil. It is my first poly finish on a piece of furniture and there are lots of things I will do differently the next time. One is that I need a better source of high intensity raking light in my shop. I missed a lot of sanding artifacts in the top and I didn’t see them until it was too late. Maybe in a few decades I’ll take the top off and sand it again and actually surface both sides, but for now it is fine and very serviceable. Lesson learned.

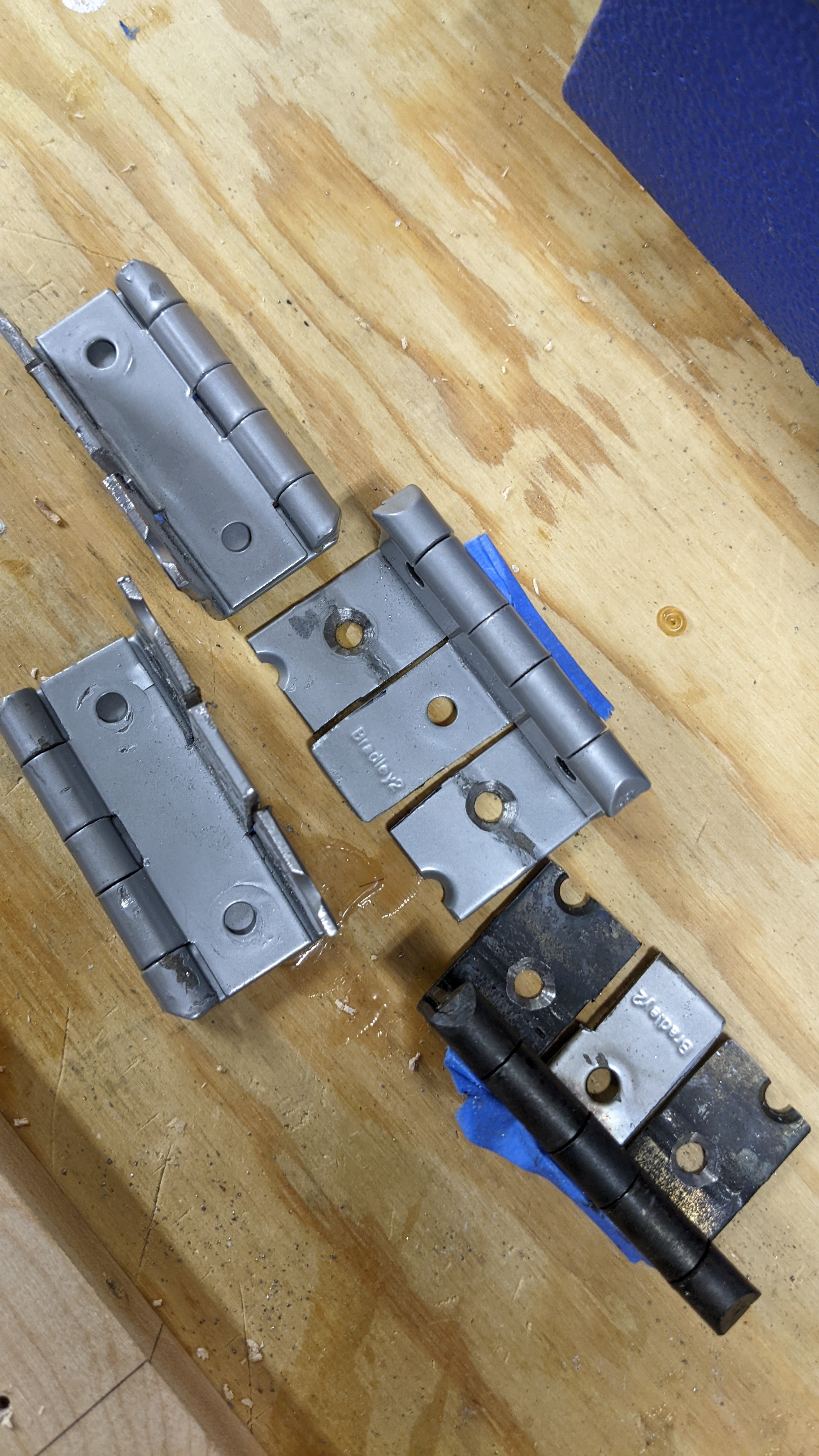

My modified hinges came out great after further trimming them on the band saw, cleaning up the edges on the sanding station and getting a wire wheel to strip/abrade the original finish off of them. I painted them black and they make a nice contrast with the natural finish. I also realized that they needed squaring up and after doing that the doors fit better with fewer washers and such. Also I didn’t need any catches to hold the doors in place when they were completely folded back.

After figuring out where the light should go I drilled a hole for it in the table top, I pressed in a oil impregnated bronze bushing so it wouldn’t destroy the wood over time. I added a hook inside the cabinet to hang the light on when it is stored. It makes set up really quick and my beautiful and talented wife doesn’t need to mess with those stupid clamps.

I added two magnetic catches to keep the doors closed and some nice knobs to the front and now everything is completed. I was originally going to cut a hole in the lift platform for wires from the sewing machine but because of the way this machine’s foot pedal works it actually makes more sense to have the wires go over the front.

I learned a lot on this one, gained some confidence with some of my tools (like the routers for example,) and I know what I need for the next finishing job.

That’s all for now, I’ll post about the next project soon.