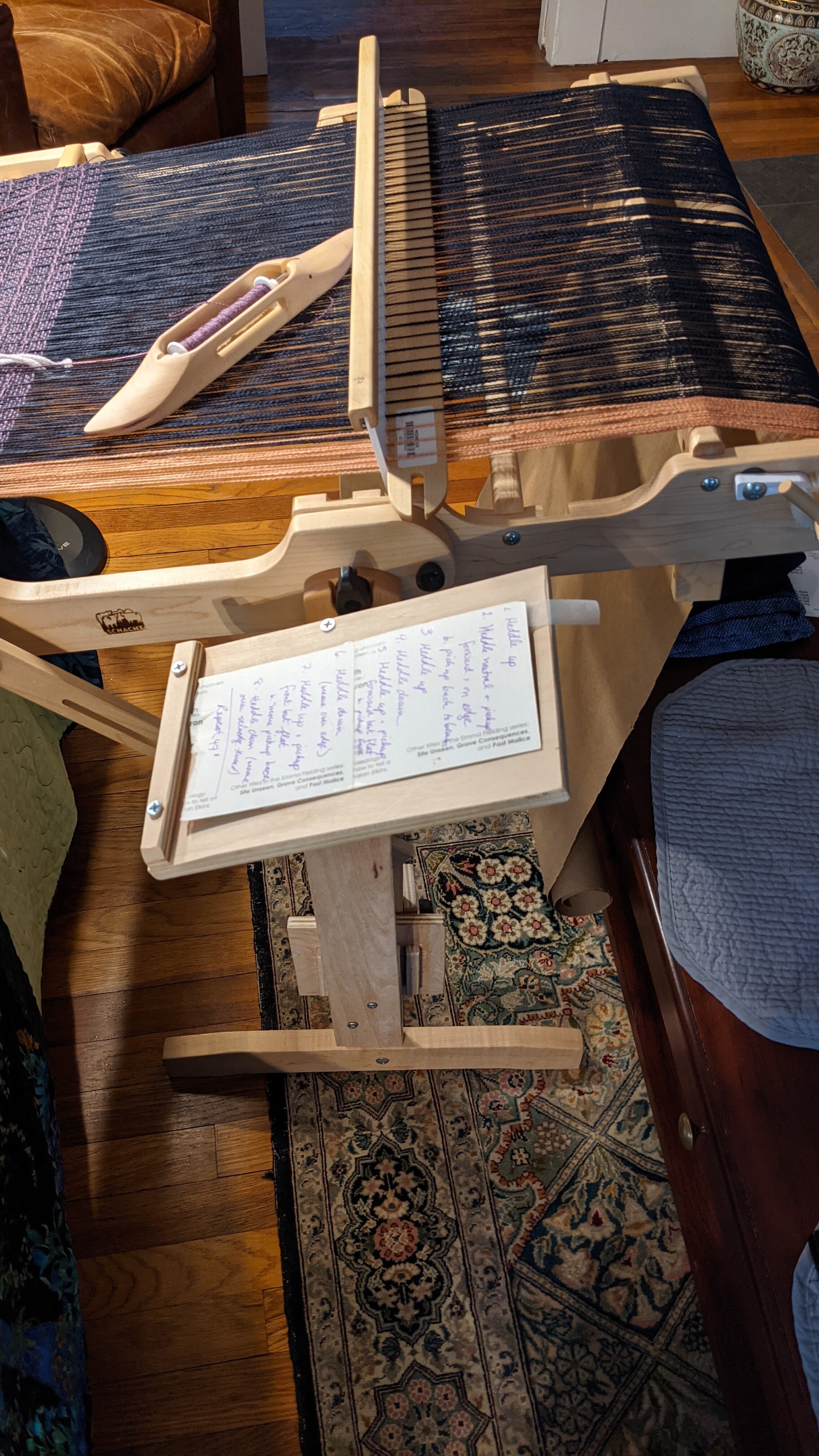

After finishing the bed project I took some time off and caught up on my comic book reading and other non-workshop activities. My beautiful and talented wife in that same time-frame went to weaving school and came back with a lot of new knowledge. One of the tools that she discovered at the school was a warp tensioning device like you see in the image above. When it is in use during the initial setting of the warp on the loom, the warp is passed over and under the rods before it passes over the beam, this helps even out the tension and make it consistent as the warp is wound up. She described it to me and showed me some pictures of them and I figured I could make one pretty easily.

I had some maple that was 1 1/16” x 9 1/2” x 24” which had some bark inclusion and milling chatter marks on one side that was perfect for making the parts for the clamping mechanism. I made a pretty detailed drawing because the clamping mechanism needed to fit the back beam of the loom fairly precisely and I wanted the center of the rods to be in line with the top of the beam.

I had to order 3/4” poplar dowels which took a few days to come, but they were nice and smooth and straight which was excellent.

The front part of clamp opens with a hinge in the front to grasp the four rods and then there is screw knob that screws down into a threaded insert in the body to clamp down on the rods. The kerf from cutting the front so it would hinge provides the difference that allows it to clamp firmly on the rods. I installed the hinge on the end with a chunk of rod clamped in the furthest hole so that the hinge would be installed to close fully without putting stress on it.

I created a bar clamp from two 1 1/16” x 1 1/16” x 5 1/2” pieces of maple with clearance through holes drilled at the ends. I couldn’t find long enough bolts at the hardware store so I got some 1/4 20 stainless all-thread rod and cut my own bolts. I used 1/4 20 wing nuts and some 1/4 20 bolts to secure them and make them hand-tightenable. I screwed the clamps to the outside of the bar holders at the matching angle to the 45 degree shoulder I cut on the bar end of each of them. The angle matches the angle of the back beam on the loom and registers everything firmly and at the right height.

I sanded everything to 320 grit and then I waxed it all with a coat of paste wax.

My beautiful and talented wife was planning to send a gift to one of her friends. It inspired me to offer to make a presentation box for the gift and so I volunteered. I had happened to have purchased some curly maple from WoodCraft when it was on sale for 70% off. I decided to make the front and the back of the box out of that material and the sides out of some Sapele left over from the bed project.

I wanted to make the panels book matched and 1/4” thick. The stock that I bought was 3/4” thick so I had to make a resawing jig for my 10” RIKON band saw. I don’t think most people would try to resaw anything with such a small and underpowered band saw but I figured I’d give it a try. I have a 1/2” 3 tooth per inch blade on my band saw and it is surprisingly rigid and cuts pretty well. I did manage to stall the band saw several times but by patiently finding the slow feed rate required I was able to cut two book matched panels 4 1/2” wide.

I edge glued them together and the resulting panel required some flattening with the sander but in the end it came out very nice. The figure on the front panel has a great “face” image of something like a snake or an alien. I got both the front and the back of the box out of one glue up. I flattened and sanded to 320 grit both sides since I wanted to finish both the outside and the inside of the box.

I have to say I thought the milling on the original blanks was pretty rough when I got them but I later realized with the curly grain going every direction it probably doesn’t plane very well.

I cut the grooves for the front and back of the box and then cut miters for the sides. I also cut a small bevel on the inside and outside of both sides of the box. I put hard wax oil finish on the panels and then installed them in box and glued it up with tape to hold and align the miters. I made sure the box was square and flat by doing the assembly on my cast-iron table saw table.

Once the glue was set I cut the box open on the table saw, sanded the new edges and then put hard wax oil finish on the outside and inside of the box.

I mounted the hardware and after a couple of days I put some paste wax on the box to add some additional sheen.

The final project was a new version of a weaving tool that I’d made before. My beautiful and talented wife has been using the tapestry/rug loom that I made for her to weave rag rugs. These are rugs that are made with strips or tubes of scrap fabric from old clothes, sheets, drapes, etc…

In order to keep the warp the same width while you’re weaving using such a heavy material for the weft, one uses a device called a temple. The temple is a stretcher placed across the warp that pulls on the edges setting the warp to a specified width. Previously I had built a temple that used spring clips to grab the warp, see below:

The device has adjustable length by sliding the center bar out and the pins secure it at a specific setting. This one worked ok but the clips were hard to secure onto bulky fabric while holding everything in place. So I agreed to make a different style that uses pointed metal teeth on the underside to grab the fabric and stretch it to the right distance.

I made it out of the same western red cedar that I made the one above and instead of using metal pins I used some 3/8” oak dowel rod to make the pins for this one, the knob head for the pins is just 1” maple rod segment drilled for 3/8” fit and then glued on and rounded.

I made the teeth out of some heavy gauge stainless steel finish nails I sharpened by spinning in the drill against the sanding disk. I cut the teeth to length using my reciprocating saw and a metal cutting blade. I glued them in using CA glue.

I sanded everything to 320 grit and then put a coat of paste wax on everything.

That’s it for now, I’m working on designing a new project and I’ll share my progress soon.